Top 10 Tips To Evaluate The Compliance Of The PAT Regulatory Compliance For PAT in Nuneaton

The UK's regulatory framework for Portable Appliance Testing, or PAT, is fundamentally different than the prescriptive requirements applicable to fixed electrical equipment and fire safety devices. Unlike fire-extinguisher maintenance, which is governed primarily by British Standards, and third-party certification programs, PAT tests are governed primarily by a health and security framework that emphasizes the duty of care, rather than a mandatory testing schedule. Electricity at Work Regulations (1989) state that electrical systems, including portable equipment, must be regularly maintained to avoid harm. The Regulations don't specify the method or frequency of testing, nor how to achieve this maintenance. In this case, it is up to the dutyholder to perform a thorough and adequate risk assessment and determine an appropriate inspection and maintenance regime. Compliance is not demonstrated solely by a pile of test results, but rather by a system of risk-based assessment, competent implementation, thorough documentation, and a documented process that demonstrates a systematic approach in ensuring electrical safety on the job.

1. Electricity at Work Regulations, 1989: The Legal Basis

Regulation 4(2), of the Electricity at Work Regulations, 1989, is the cornerstone for PAT compliance. It states: "As necessary to prevent dangers, all systems must be maintained to prevent such dangers, as far as it is reasonably practicable." The duty to maintain electrical equipment is a legal obligation for employers and other dutyholders. The term system includes portable appliances. The regulations don't mention "PAT tests" in particular; instead, they require "maintenance," a concept that encompasses visual inspection, user check, and combined inspection and test. The risk assessment determines the frequency and type required of maintenance, not a set legal schedule.

2. Act 1974: The role of Health and Safety at Work Act 1974

The Health and Safety at Work (etc.) Act 1974 is the overarching legislation which establishes the general duties employers have towards employees and others. Act 1974 is the overarching legislation that establishes the general duties employers have towards employees and others. According to Section 2 of this Act, employers must ensure that all employees are safe and healthy, in the best way possible. This includes providing safe plant and systems of work, which encompasses electrical equipment. In Section 3, this duty extends to those not under their employment such as visitors and contractors. The PAT test process is one of the most effective ways to meet these duties. It provides a systematic approach for ensuring electrical safety.

3. Guidance and Best Practice: The IET Code of Practice for In-Service Inspection and Testing of Electrical Equipment

The Institution of Engineering and Technology Code of Practice, while not a law in itself, is widely accepted as the benchmark for best practices when it comes to PAT testing. It includes detailed instructions on how to implement a maintenance program that is compliant, including:

Definitions for appliance types and classes

Detailed procedures for formal visual inspections and combined inspection and testing.

Initial recommended frequency for inspections and tests based on the equipment type and operating conditions.

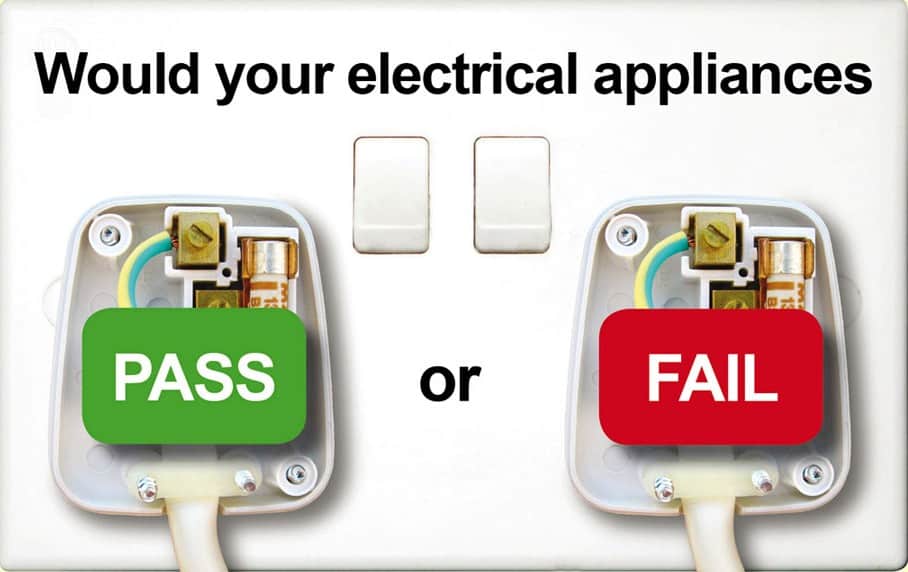

Pass/fail criteria for test results.

Courts and Health and Safety Executives (HSE) inspectors use this code as a standard to judge the suitability and sufficiency of a dutyholder’s routine maintenance. A deviation from the code that is not accompanied by a documented and robust risk-based justification can be interpreted as non-compliance with the regulations.

4. Risk Assessment is the Priority

HSE has explicitly advocated a PAT-based risk-based testing approach. It is moving away from outdated concepts of blanket annual testing. The dutyholder must conduct a risk assessment to determine the need, nature, and frequency of inspection and testing. These factors are important in determining the outcome of this risk assessment.

Equipment type. A Class I appliance, in a workshop or low-risk environment, may require regular formal testing.

Construction sites, workshops, and warehouses present a high level of risk. Hotels and offices are usually lower risk.

Are users of equipment trained staff, or are they members of the general public.

The appliance's history: Has it been damaged or is it new?

A compliant system is defined by this risk assessment, not by the volume of tests conducted.

5. The Concept of Competence for Testers

Regulation 16 of the Electricity at Work Regulations 1989 requires that persons engaged in work on electrical systems must possess the necessary technical knowledge and experience to avoid danger. In PAT tests, "competence", does not always require formal qualification. However, the tester must possess:

Knowledge of electricity is essential.

Practical experience and understanding of the system they are working on.

Understand the risks and precautions that are required.

Ability to correctly use the test equipment and interpret the results.

City & Guilds2377 is a popular qualification which provides excellent training. However competence can be obtained through alternative means. The dutyholder should be able prove that the person performing the testing has the necessary qualifications.

6. Documentation and record-keeping requirements

The Electricity at Work Regulations are not explicit in their requirement for record keeping. Regulation 29 however states that proving due diligence and taking all reasonable steps in order to avoid committing the offense is a defence. Comprehensive records are the primary evidence of due diligence. A compliant records-keeping system includes:

The asset register is a list of all equipment.

A record of the risk assessment and the resulting maintenance plan.

Detailed reports for each formal inspection and test, including appliance description, test results, pass/fail status, date of next test, and tester's identity.

HSE officials or local authorities should be able to easily inspect these records.

7. Labelling and Identification of Appliances

Effective labelling is essential to a compliance PAT system. Each appliance that's been subjected to a combined inspection and testing should be labeled with:

The unique ID number of the asset that links it to the record.

The test date.

The date for your next test.

The name of the tester or its identifier.

The label provides a clear visual indicator of an appliance's compliance status for users and inspectors. Labels must be durable, nonmetallic and nonconductive.

8. The HSE Enforcement Position and "Myth-Busting".

The HSE has actively worked to clarify misconceptions about PAT testing. They stress that:

No legal requirements exists for equipment to be tested annually.

There is no requirement for businesses to hire a third party contractor if they are able to test themselves.

Visual inspection can often be more effective than electronic testing in identifying the majority of faults.

An enforcement official will consider a risk-based strategy. A company testing equipment without risk assessment every year may be looked down upon by enforcement officers.

9. Interaction with Other Legislation : PUWER

The Provision and Use of Work Equipment Regulations of 1988 (PUWER), applies also to portable devices. PUWER requires that work equipment be suitable for its intended use, maintained in a safe state, and inspected to ensure it remains safe. Regulation 6 requires inspections when safety depends on installation conditions. The PUWER inspection and maintenance regulations for electrical work equipment are met by PAT testing, which is a critical method.

10. Insurance Implications and Due Diligence

Insurance companies can have their own requirements, even though the law is based upon risk assessment. Insurance policies may require that third parties conduct PAT testing annually as a requirement for coverage. Unable to comply with this requirement could invalidate your claim. Insurance companies and HSE will also scrutinize the dutyholder’s risk assessment and PAT testing records in the event that an electrical incident occurs. A risk-based, well-documented system is a powerful defence to prosecution or invalidated claims. Follow the most popular electrical equipment testing in Nuneaton for site examples.

Top 10 Tips On The Compliance Of The Regulatory Compliance Of The Fire Extinguisher Maintenance in Nuneaton

The UK regulatory framework for fire extinguisher service is a complete system that is designed to ensure equipment reliability and public security through clearly defined legal requirements, technological standards, and certification schemes. Fire extinguisher services are governed by specific legal requirements in contrast to some safety regulations that provide broad guidelines. These are supported by standards for technical performance as well as third-party certification programmes as well as detailed reforms to the regulation (Fire Safety) Orders, which create an organized compliance PAThway. This multi-layered strategy places all responsibility on the "Responsible person" of each facility to ensure proper maintenance, and provides clear benchmarks that provide proof of the due diligence. The understanding of this framework is vital not only to ensure legal compliance but as well to ensure that the fire protection equipment work as expected in emergencies, ultimately ensuring the lives of people, property, and business continuity, while also complying with insurance requirements and avoiding significant legal penalties.

1. The Regulatory Reform (Fire Safety) Order 2005 (FSO) in Nuneaton

The Fire Scotland Act of 2006 as well as similar regulations in Northern Ireland and Scotland, form the basis for laws governing fire safety in England and Wales. Article 17 specifies that all equipment used to fight fires must "be maintained in a proper routine of maintenance to ensure it is in effective condition, functioning efficiently and in good working order." This obligation falls to the "Responsible person" (typically an employer, owner or occupier) who is legally accountable for ensuring that all fire safety equipment, including portable extinguishers are maintained in a good state in good working order, efficient and excellent condition.

2. British Standard BS 5306-3:2017

This standard sets out the technical guidelines to ensure compliance with the FSO, detailing the specific requirements for the commissioning and maintenance of portable fire extinguishers. It defines the different kinds of services: basic (annual visual inspection and easy checks) as well as extended service (discharge test and internal examination every five years for foam, water and powder extinguishers) as well as overhaul (pressure test and internal examination every 10 years for CO2 extinguishers). Conformity with BS 5306-3 can serve as a reference to show the "suitable" maintenance procedure as required by law.

3. Third-Party Certified Schemes in Nuneaton

Although it isn't legally required using a BAFE (British Approvals for Fire Equipment) SP101 certified provider provides the most thorough proof of due diligence. This UKAS-accredited scheme of certification independently confirms that a business has met the strictest standards for technical expertise, quality of work, business processes, and equipment. BAFE certification has been recognized by courts, fire authorities and insurers as evidence that a company is in compliance with FSO standards regarding maintenance.

4. Fire Risk Assessment: What is it? in Nuneaton

Fire Risk Assessments (FRAs) are dynamic documents that guide all fire safety-related decisions, which include extinguisher service. It is required to identify the correct fire-fighting equipment, identify its proper size, type and Nuneaton, and define the required maintenance schedule. FRAs should be regularly inspected, especially when circumstances change. Any changes must be recorded in any servicing schedule. The reports of the service provider often offer valuable insight for the reviews.

5. Documentation and evidence is a requirement. in Nuneaton

For compliance reasons, it's vital to have a thorough documentation. After each service, the company should issue a report with the company's details including engineer's details and service dates, a descriptions and lists of the services performed, equipment, and any faults that are identified. The reports should be easily accessible for inspection by enforcement officials (Fire and Rescue Services) as well as insurance providers. The absence of adequate documentation could result in sanctions even though the service was actually performed.

6. Sanctions and Enforcement Mechanisms in Nuneaton

Local Fire and Rescue Authorities have extensive enforcement powers and conduct audits to determine compliance. In cases of non-compliance to the requirements for servicing local Fire and rescue Authorities can issue: Amendment Notices that require specific improvements in a given time frame, Enforcement Notices that mandate specific changes or, in the event that the issue is serious, Prohibition Warnings which immediately stop or block the Nuneaton. The courts have the power to impose unlimited fines and even up to two years in prison for serious infractions.

7. Impacts of Insurance in Nuneaton

Commercial insurance policies usually contain an obligation to comply with the law regarding fire safety. Following an incident, insurance coverage may be void if the provider is not compliant or has no documents. Insurance assessors require servicing records in the course of processing claims. Insurance companies may also require specific certification standards, such as BAFE Sp101 as an obligation for protection, particularly in large commercial buildings and in high-risk properties. policies.

8. Qualifications for Technicians in Nuneaton

The FSO requires that maintenance be done by "a competent person." While not legally defined, competence generally includes: formal training on BS 5306-3, manufacturer-specific equipment training, practical experience, and understanding of relevant regulations. Third-party certification schemes such as BAFE SP101 offer the best guarantee of proficiency for technicians by regular assessments and audits.

9. Environmental Compliance in Nuneaton

Environmental laws, including the Environmental Protection Act of 1990 regulates the how to dispose of waste. Registered waste carriers must provide Waste Transfer Notes. Responsible people must make sure that the company they select adheres to all laws and regulations. This is because they are ultimately responsible for the disposal of their waste and may be penalized if they fail to do so.

10. What is the frequency and extent do services are required? in Nuneaton

To be in compliance with BS 536-3 that the following frequencies of service should be observed: annually service for all types of extinguishers (water, foam and powder), extended service once every 5 years and a thorough overhaul at least every 10 years. In addition, the Responsible person must make sure that inspections of all extinguishers is conducted every month (often by employees) in order to find obvious issues like obstructions, damage and pressure loss. This combination between professional servicing and user inspections creates the basis for a maintenance plan. View the best fire extinguisher checks in Nuneaton for more examples.